The stiffening of the perpendicular magnetic tunnel junction (pMTJ) stack resulting from the W insertion due to its very high melting temperature, is the key mechanism behind the extremely high thermal robustness. Thicker W layer in the W(t)/Ta 1 nm cap layer makes the storage electrode of pMTJ stack highly robust against annealing up to 570 °C.

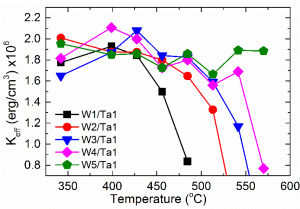

W in the cap layer of storage electrode (buffer/MgO/FeCoB/Cap) boosts up annealing stability and increases the effective perpendicular anisotropy by 30% compared to Ta cap. Correspondingly, an increase in the FeCoB critical thickness characterizing the transition from perpendicular to in-plane anisotropy was observed. Thicker W layer in the W(t)/Ta 1 nm cap layer makes the storage electrode highly robust against annealing up to 570 °C as shown in the figure below. The stiffening of the overall stack resulting from the W insertion due to its very high melting temperature and efficient Boron absorption from FeCoB by W are the reasons of such extreme thermal robustness of storage electrode. The Gilbert damping constant of FeCoB with W/Ta cap was found to be lower compared with Ta cap and stable with annealing. The evolution of the magnetic properties of bottom pinned p-MTJ stack with W2/Ta1 nm cap layer shows back-end-of-line compatibility with increasing TMR up to annealing temperature of 425 °C. The pMTJ thermal budget is limited by the synthetic antiferromagnetic hard layer which is stable up to 425 °C annealing temperature while the storage layer is stable up to 455 °C.

Figure: Effective perpendicular magnetic anisotropy (Keff) of perpendicular storage electrode of MTJ stack with W (1,2,3,4 & 5) / Ta 1nm cap as a function of annealing temperature.

Contact: Bernard DIENY@cea.fr ; Ricardo SOUSA