Increasing the thermal budget beyond 400°C of magnetic random access memory (MRAM) cells is a major goal to allow for seamless conventional electronics integration. At these temperatures significant material diffusion can destroy the interface properties of new generation perpendicular magnetization stacks targeting technology nodes below 20nm. This study highlights the origin in the improvement obtained with tungsten capping layers.

Recent offerings of Magnetic Random Access Memory (MRAM) in embedded CMOS designs is a trend emerging at the most advanced foundries. These cells rely on perpendicular anisotropy magnetic tunnel junctions, which are a typical layer stacks comprising thin layers of 8 or more materials, each one having a specific contribution to the cell performance. Improvements in tunnel magnetoresistance (TMR) and in cell retention are high up on the requirement list. TMR signal allows for faster read times with targets set at the ns level to achieve parity with SRAM cells. High TMR ca be achieved at higher annealing temperatures over 400°C. However, elemental diffusion forces to compromise at lower temperatures.

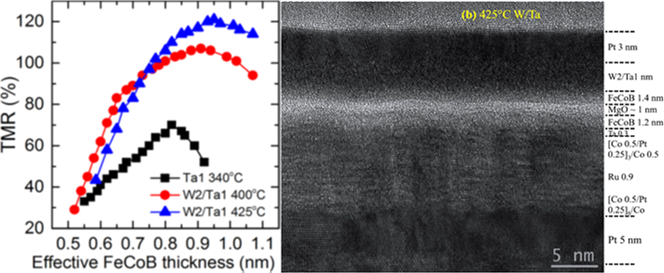

Spintec’s research has highlighted that the loss of TMR at high temperatures can be traced back to diffusion of Fe away from the MgO tunnel barrier and towards the top electrode capping layer. For capping layers made of Ta the maximum annealing temperature is below 400°C. The work demonstrated that adding a refractory material as W above the FeCoB top electrode it is possible to increase the annealing temperature to 425°C, leading to almost a doubling of TMR from 70% to 120%. In fact, tungsten blocks the diffusion of Fe maintaining the perpendicular anisotropy at higher temperatures. As a welcome consequence the cell information retention time also improves by 50%, allowing for 10 year storage times at dimensions close to 20nm. Achieving a higher annealing stability is important for integration with CMOS devices, since typical high pressure deuterium annealing steps to improve transistor performance are done at 400°C.

Team: MRAM Team

Funding: ERC Adv grant (MAGICAL No. 669204)

Further reading: Physicochemical origin of improvement of magnetic and transport properties of STT-MRAM cells using tungsten on FeCoB storage layer, J. Chatterjee, E. Gautier, M. Veillerot, R.C. Sousa, S. Auffret, B. Dieny, Appl. Phys. Lett. 114, 092407. (2019). DOI: 10.1063/1.5081912

Contact: Ricardo Sousa, Bernard Dieny

Figure: TMR signal of FeCoB storage electrode with W/Ta capping layers. Improvement by high temperature annealing is only possible with W cap. It prevents loss of Fe from the top FeCoB electrode, illustrated in stack cross section annealed at 425°C.